Application of ultrafiltration

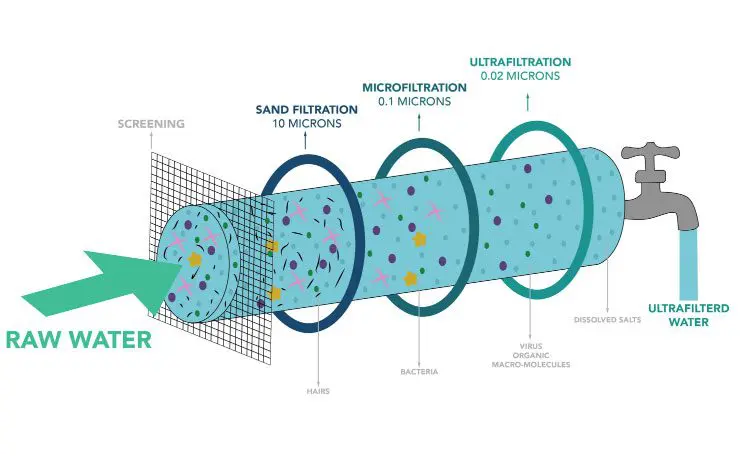

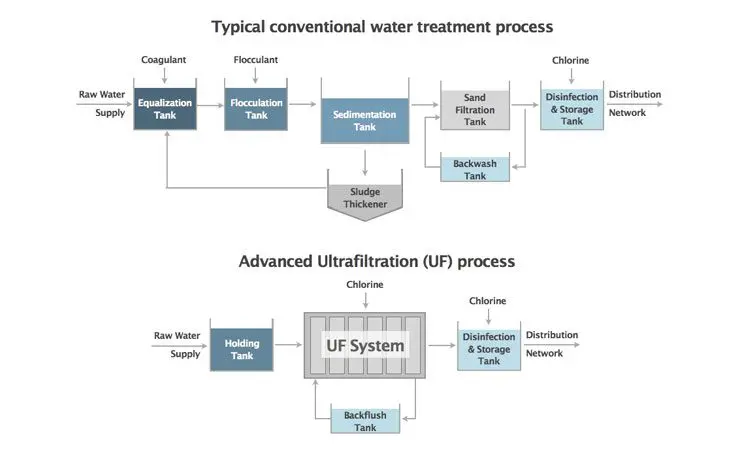

As mentioned, water treatment removes suspended particles, mud, heavy metals, and even microorganisms, viruses, and germs from the water. According to the procedure and also how ultrafiltration works in different environments and for different purposes, the most important of which can be mentioned as follows:

UF ultrafiltration in industrial applications

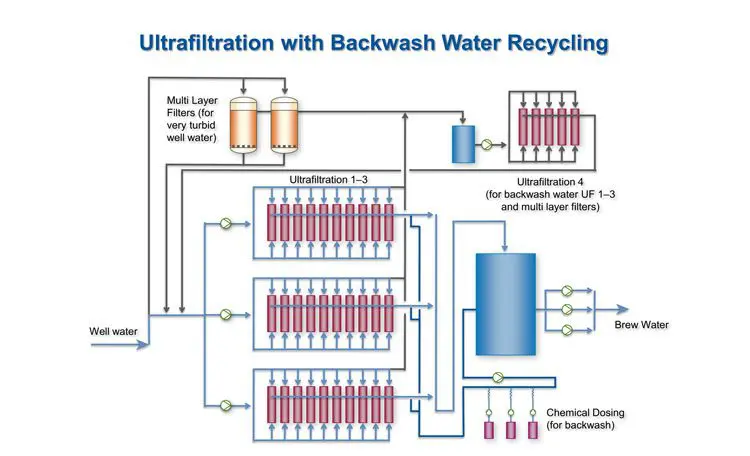

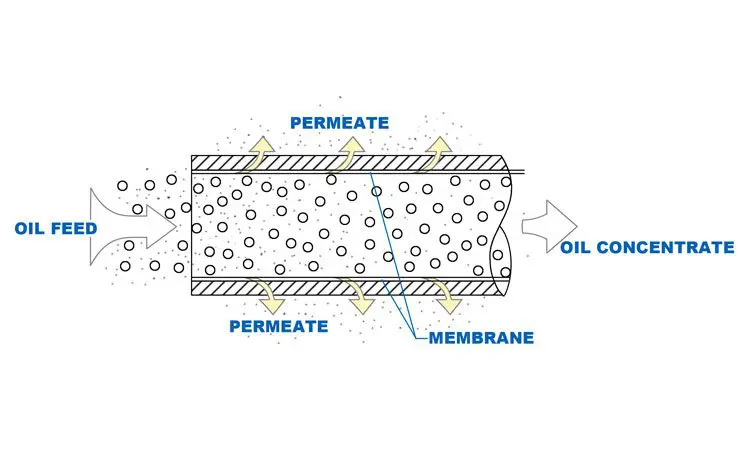

One of the main applications of ultrafiltration is in the industrial sector and wastewater treatment of factories and production workshops. Due to its ability to remove organic matter, oils, greases, colloidal particles as well as proteins, the ultrafiltration water treatment package can be used in food and pharmaceutical industries as well as various factories. In addition, this treatment method is very useful for removing contaminants in pond water, rivers and industrial effluents and causes water to circulate.

Of course, it should be noted that ultrafiltration method is very useful not only in water treatment, but also in textile factories, dairy and protein and food as well as pharmaceuticals and has the ability to remove enzymes, amino acids and dyes in wastewater.

Ultrafiltration in domestic use

The presence of salts and minerals in drinking water is one of the biggest problems that people in most areas face. In addition, in some areas, access to drinking and treated water may not be possible and various diseases may occur in these conditions. By using the ultrafiltration water purification package, completely pure water can be easily obtained without any contamination.

Use of UF ultrafiltration in reverse osmosis

Reverse osmosis, which is one of the most practical methods in water treatment, works with semi-permeable membranes. In many cases, ultrafiltration can be used in the pre-treatment stage to remove large amounts of contaminants, organic matter and waste from the water, and as a result, reverse osmosis filters and membranes will last longer. In addition, the use of UF eliminates the need to add chlorine or ozone to the water, thus preventing the RO filter from perforating.

Leave a Reply