Price of activated carbon filter

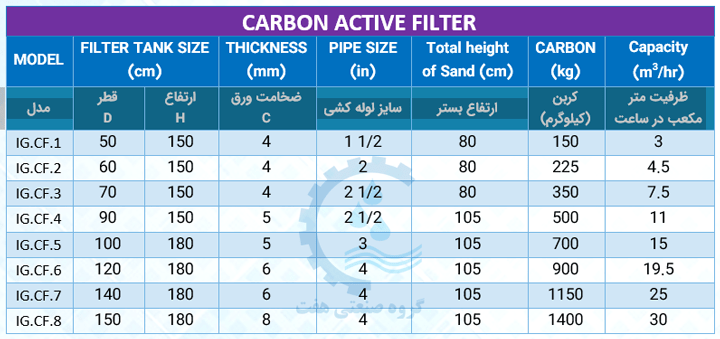

When buying a carbon filter, in addition to paying attention to the quality and efficiency of the device, it is necessary to consider the price of the carbon filter. The difference between the price of activated carbon filter produced and available in the market depends on several important factors, the most important of which are the manufacturer brand, size, model, body material and amount of carbon. For information on the price of carbon filter produced by Haft Industrial Group, you can use the communication channels mentioned at the bottom of the page.

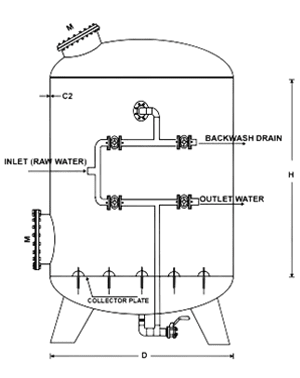

Design and production of carbon filter

Haft Industrial Group, as one of the most experienced collections of industrial water and wastewater treatment equipment, has designed and produced carbon filter in its activities. In the design and manufacture of activated carbon filter in this group of engineers with experience and expertise in the field of water and wastewater and all the necessary standards are used during the design of each product. Due to the very high diversity of Haft Industrial Group products and assigning unique features to each of them, the experts of this collection provide the necessary tips and advice before buying carbon filters and other equipment.

Leave a Reply