API degreasing package design

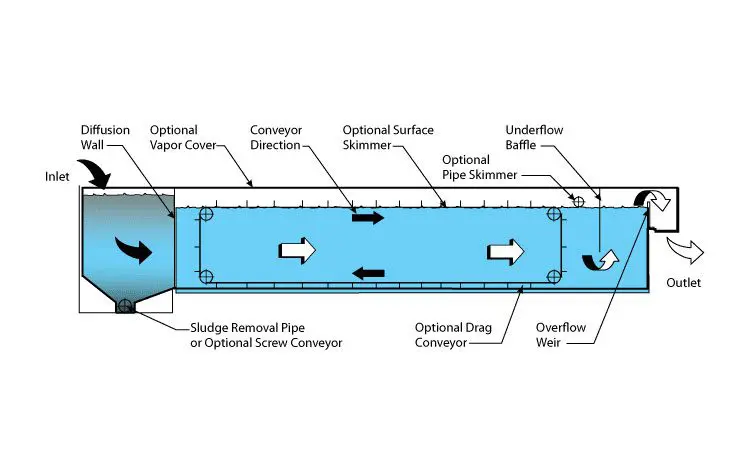

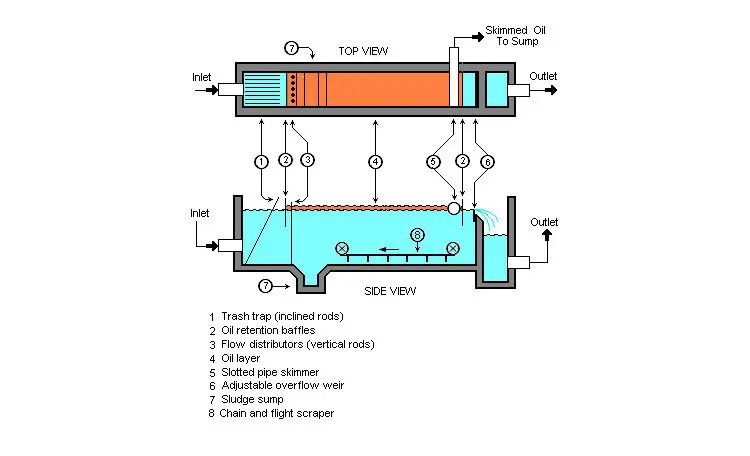

API degreaser design is based on the standards of the American Petroleum Institute and depending on the type of wastewater and suspended solids in it, it is necessary to consider various factors during the design. For example, in the design of the API wastewater degreasing package, the temperature of the wastewater entering the device is considered to be more than 5 degrees. In other words, wastewater treatment with a temperature of less than 5 degrees will not be done well in this way. Time of settling of solid particles in the bottom of the tank and transfer of light particles to the water surface based on their size, time of presence of water in the tank for separation of particles, oil density, amount of hydrocarbons in the sewage and body material and other equipment in the device based The type of sewage is one of the things that should be considered in the design of degreasers.

Manufacture of API grease trap

Seven Industrial Group is one of the largest design, production and manufacturing teams of API degreasing package in Iran. All stages of work in this complex are carried out under the supervision of professional engineers with experience in the field of water and wastewater treatment. It should be noted that Seven Industrial Group designs and manufactures API degreasers according to the environmental conditions used and the type of wastewater and colloidal materials in it. Therefore, there is a big difference in the products of this collection in terms of size, dimensions, material and equipment in them. The experts of this collection are ready to provide free advice and tips for purchasing API degreasers through the following communication channels.

API degreasing system price

The price of API degreaser is determined according to the size and dimensions of the device and tank, body material, fittings and equipment in it. As a result, the price difference in these products is very large, and you can contact the Seven Industrial Group to inquire about the price of API degreaser.

Application of API degreasing package

The first reason for designing and producing the API degreaser package by the American Petroleum Institute was to separate oil particles and oil from the water in the refineries. Gradually, the use of this equipment expanded so that now these devices can be used in various environments such as the following.

• Refinery wastewater treatment

• Separation of oil particles from wastewater of petrochemical industries

• Separation of oil particles from water for use in substation transformers

• Separation of colloidal particles from ship effluents in ports and the sea

Advantages of API degreaser

The use of oil particle removal systems from water, despite its limitations, has many advantages and therefore can be a good option for treatment in environments with relatively low wastewater. One of the most important advantages of these devices is easy design in a short time. In addition, this group of wastewater treatment equipment has low energy consumption and is suitable for environments with temperatures above 5 ° C and particles with a size of less than 150 microns.

Leave a Reply