UASB system price

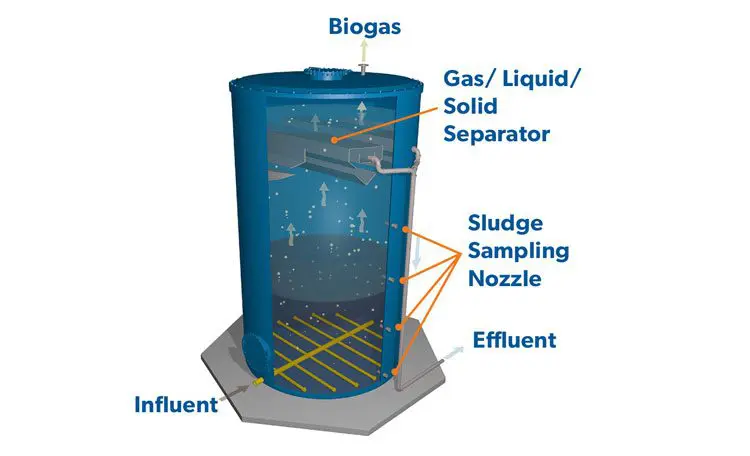

Anaerobic wastewater treatment reactors are one of the most complex equipments in the field of wastewater treatment, which in addition to many differences in their types, are also different in terms of price. The price of UASB reactor is determined based on various factors, including the body material, size and capacity of the tank, brand and materials used in the equipment and fittings of the device, height, etc. You can use the communication channels at the bottom of the page to inquire about the price of the UASB wastewater treatment package.

Application of UASB wastewater treatment

As mentioned, the upstream anaerobic sludge blanket (UASB) wastewater treatment system has the ability to separate organic matter from industrial and sanitary wastewater. Therefore, this equipment is mostly used as wastewater pre-treatment in various industries. The most important applications of UASB treatment system are the following:

Use of UASB reactors in beverage factories

Factories and food industries

Paper industry

Alcohol production

Textile wastewater treatment

Advantages of UASB

UASB treatment system has many advantages over aerobic reactors, the most important of which are:

· No need for sludge layer food for long

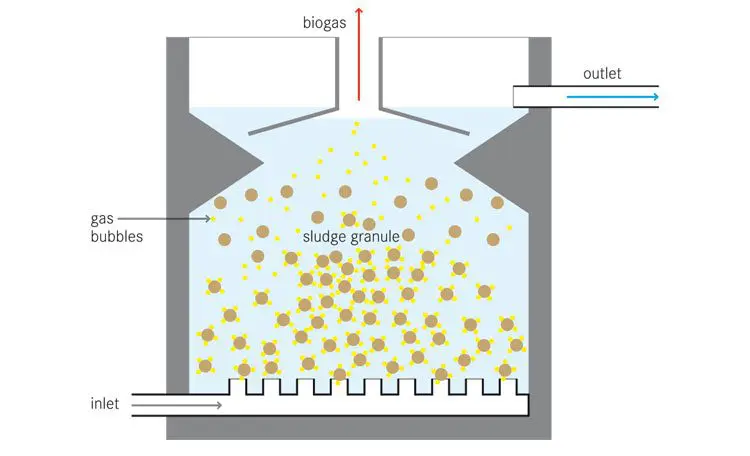

· Production of biogas in the process of reaction of organic matter with biological waste and production of energy from them

· Production of concentrated sludge and its use in agricultural fields

· High efficiency in the removal of organic matter from industrial and sanitary wastewater

· Low space required for installation of USAB wastewater treatment system

· Low odor production compared to aerobic methods

· Cheaper cost to build, install and maintain

Disadvantages of Anaerobic Wastewater Treatment

Despite all the advantages of anaerobic wastewater treatment systems, this equipment has limitations, but many of them can be addressed by various methods. Among the disadvantages of anaerobic wastewater treatment reactors are the following options:

· Lack of proper performance in low temperature environments

· Inability to remove all contaminants in the wastewater and the need for a complete treatment stage after the wastewater leaves the anaerobic system

· Time consuming stage of designing, manufacturing and producing USAB wastewater treatment package

Leave a Reply