CPI degreaser design

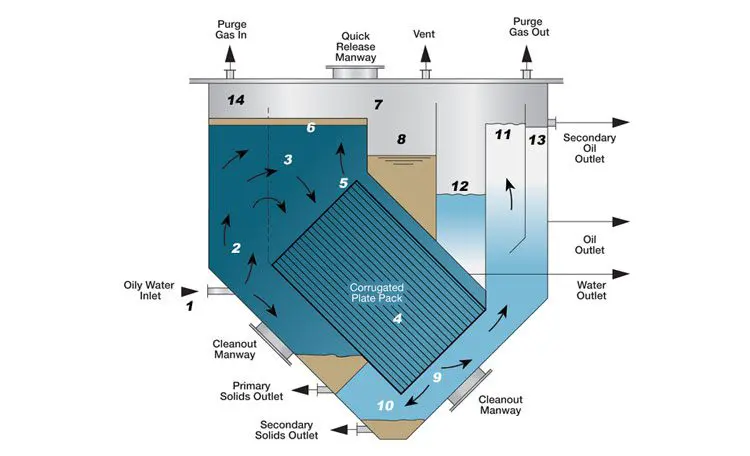

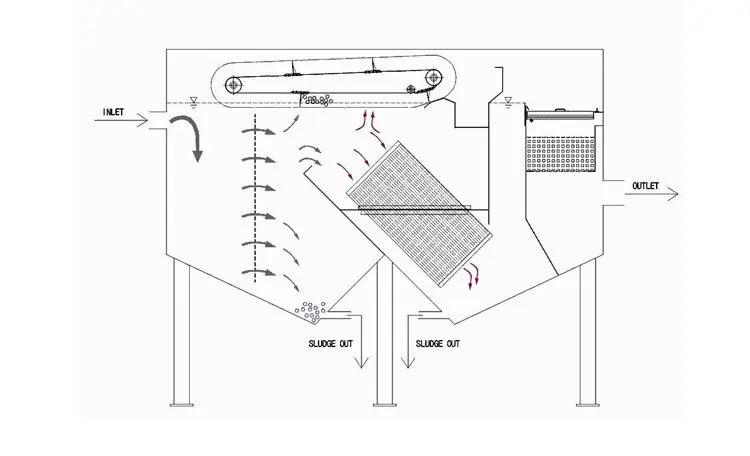

In order to increase the efficiency of the CPI separator, several standards have been considered and it is necessary to consider various factors for better design. The most important things to consider in CPI degreaser design are ambient and wastewater temperature, type of wastewater and liquid and solids in it, density of colloidal particles, rate of sedimentation of solids, rate of oil particles transfer to the surface, rate They are overflows. Accordingly, and according to the time required to settle or transfer particles to the surface and the type of wastewater and other factors, the angle of placement of the plates and their number, as well as the material used in the production of plates is determined. In addition, the material used to make the body of the device as well as the plates must be selected in such a way that it does not corrode in contact with industrial wastewater. In other words, the design and production of CPI wastewater degreaser for various industrial and semi-industrial environments must be completely unique in order to receive proper efficiency from the device.

Making CPI degreaser

Due to the very wide application of CPI wastewater separation device in various industries and their high efficiency in wastewater clarification, the industrial group has included the design, production and manufacture of degreasers by CPI method in its set of activities. It should be noted that this complex is one of the most experienced production teams of water treatment equipment in Iran, which has succeeded in implementing various domestic and international projects in this field. Observance of international standards in all stages of CPI production and performing activities under the supervision of engineers and professors with experience in this field and unique product design according to the desired environmental conditions are the most important features of Haft Industrial Group products. In order to receive information about the specifications of these products, the experts of Haft Industrial Group are ready to provide a free consultation before purchasing the CPI degreasing package through the communication channels mentioned at the bottom of the page.

CPI degreaser package price

CPI degreasing device is designed and produced according to the type of wastewater, the amount of wastewater entering the device, environmental conditions, the size and dimensions of the device and the body and case material, the number of plates, etc. Therefore, there is a difference in the price of CPI degreaser in different models of these products. To inquire about the price of CPI degreaser, we suggest that you contact Haft Industrial Group.

Application of CPI degreasing device

Due to the high efficiency of CPI degreasing devices and the ability to separate particles with a size of 50 microns, this group of products is used in various industrial and semi-industrial industries. However, it should be noted that despite the many advantages of this equipment, compared to the API, they cannot tolerate a sudden increase in organic load. That is why in refineries, APIs are mostly used to separate colloidal particles. The main uses of CPI include the following:

· Separation of oil and fat particles from effluents in food industry

· Refineries

· Industries and factories active in the field of petrochemicals

· Detergent and sanitary factories

· Factories producing paints and other chemicals

Advantages of CPI degreasing system

· The main reason for the widespread use of CPI over other gravity separators is the many advantages of this device, which include:

· High efficiency in removing oily and colloidal particles with a size of at least 50 microns

· Separation of liquid and solid particles from wastewater with low energy consumption

· Low cost design, construction and installation in a short time

· Easy maintenance with low cost

· Separation of particles in a short time due to the use of diagonal and parallel plates in the tank of the device

· Requires little space for installation

· Cleansing sewage without creating an unpleasant odor

· High performance in different environmental conditions

· Improve device performance by adding new pages in no time and without the need for redesign

· No need to turn off the CPI device to repair it

· Ability to design and manufacture CPI degreasing device according to the type of wastewater

· Easy drainage of sludge deposited on the bottom of the tank and collection of oily layers on the surface of the sewer

Contrary to the features intended for the production of CPI wastewater degreasing package, API devices have the ability to separate oily and solid particles with a size of at least 150 microns, and repair and upgrade of the device requires more cost and time. This is why CPI is being replaced by API in most industries. In order to receive more information about these products, specifications and features of each and inquire about the price of CPI degreaser, you can contact the experts of Haft Industrial Group through the communication channels mentioned at the bottom of the page and receive a free consultation.

Leave a Reply