Chain driven belt screen

In this type of filter, the process of collecting the accumulated garbage on the screen is done by chains and a rake. This process is done periodically and after increasing the amount of waste and completely automatically. One of the biggest disadvantages of this type of filter is the reduction of chain life due to its constant presence in water.

Traveling bar screen

This type of filter is actually the same as the manual type, with the difference that the lowering of the rake to collect garbage and transfer it to the top of the device is done automatically. One of the best features of this type of filter is that the rake is out of the water, which makes it have a longer life than the type of chain drive.

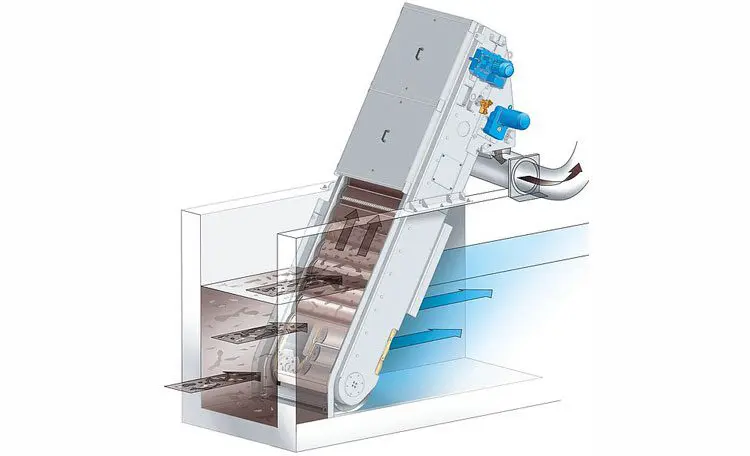

Belt screen

As the name implies, this group of filters uses a belt-like perforated screen in their structure, which moves through the gears installed in the machine after collecting garbage. One of the best advantages of this type of bar screen is that the electrical parts of the device are out of water.

Raked bar screen design

In designing a Raked bar screen, like other types, it is necessary to consider several important factors and make calculations accordingly. One of the most important of these is the distance between the rods, which is determined by the fine or coarse nature of the waste. But the most common size for this purpose is 10 to 50 mm. In addition, it is necessary to measure the width of the bars, for which 10 mm will be suitable. Other important factors in the design and production of Raked bar screen include the speed of sewage through the canal, which is considered to be about 0.3 to 0.9 meters per second. In a mechanical bar screen, the angle of the bars in relation to the surface should be considered, so that 45 to 60 degrees is one of the best conditions for their installation in order to increase the efficiency and effectiveness of the device.

Benefits of Raked bar screen

Mechanical bar screen Raked have more applications than the manual type. The wide selection and purchase of this group of filters in the first stage is due to their many advantages, which are:

· High efficiency and effectiveness in treatment plants with a capacity of more than 1000 cubic meters

· Reduce costs due to the lack of manpower in the process of collecting garbage on the screen

· Reduce human error due to the automation of all processes

· Easy installation, repair and maintenance

· High corrosion resistance due to the material used in various parts of the device

· High efficiency in removal of suspended solids (2 to 3 mg / l)

Manufacturing and producing Raked bar screen

Due to the very important role of pollutants in industrial and semi-industrial treatment plants, Seven Industrial Group has made the production of Raked bar screen with the latest standards in its activities. This collection uses the experience and knowledge of experts and engineers in the field of water and wastewater treatment to design and manufacture Raked bar screens, and currently offers its products to refineries and large industrial and semi-industrial companies. The experts of Seven Industrial Group provide the necessary advice for selecting and purchasing a Raked bar screen according to the intended application through the communication channels mentioned at the bottom of the page.

Raked bar screen price

The price of Raked bar screen is determined according to its type, the material used for the bars and mesh screen, their dimensions and capacity, and other items that have been considered in the production process. For this reason, there is a lot of variation in the price of this device and their price cannot be announced accurately and consistently. In order to inquire about the price of Raked bar screen, you can contact Seven Industrial Group.

Leave a Reply