U-shaped coiled tanks

As the name of this group indicates, copper pipes are installed in the form of the letter U in the tank, the number of pipes is determined as needed and in most cases will be more than one pipe. One of the main reasons for using this type of coils is to increase the performance and efficiency of the device. So that after blocking or causing damage in a pipe, there is no disturbance in the operation of the tank and hot water and steam can flow in other pipes and supply hot water.

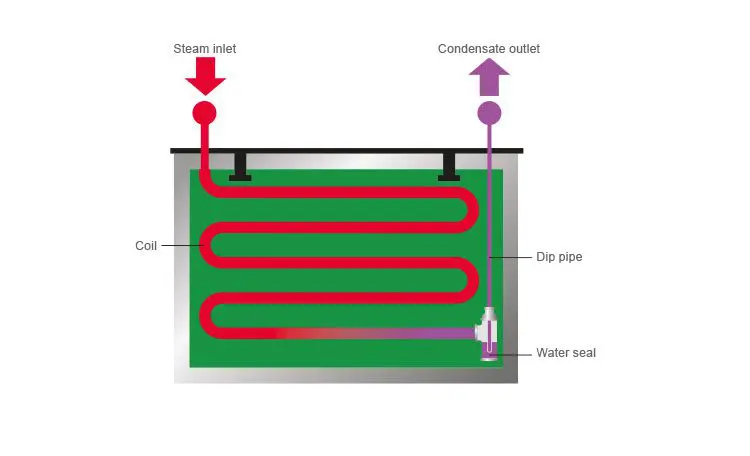

Helically coiled tank

Unlike the U-shaped type, in a helically coiled tank, the hot water flow is present only in a coil-structured tube, which heats the cold water in the tank. One of the biggest disadvantages of this type of coiled tank is the failure of the device in case of damage to the coil pipe. Because only one coil with a helical structure is installed inside the body, as a result of its breakdown or blockage, it will not be possible for hot water and boiler steam to pass through it.

Water to water and steam to water tank

Depending on how the energy and heat required to increase the temperature of the water in the coil are supplied, they can be divided into two groups: water to water and steam to water. As the name implies, the water-to-water tank uses the hot water to absorb the energy needed to heat the water in the coil, and if steam is used for this purpose, it is steam to water.

twin coil tank

In this type of tank, as its name implies, two coil tanks are used. The reason for using these two tanks is because one of the tanks is connected to the solar heating system and the other to the boiler. With this solution, if the solar energy is not enough to heat the water, then the boiler can provide the required heat.

Coiled tanks components

In order to implement the operation of coiled tanks mentioned above, it is necessary to use different components and equipment in the structure of coiled tanks. The main components used in these tanks are:

Cylindrical body

Cylindrical body is one of the most important components of the tank, in order to increase its resistance to pressure, sediment and corrosion, galvanized sheets are used for it. Dimensions, capacity and volume of coiled tanks are determined according to the place of installation and use, and therefore there is a lot of variety in it. Hulls made for coiled tanks are installed on the base in two standing and horizontal positions.

Galvanized sheets and sometimes black steel are used to design and build the tank body. These sheets have a high resistance to temperature and pressure, and therefore the safety factor of the device will increase to a desirable level. It should be noted, however, that unlike galvanized sheets, which are stainless and corrosive, tanks made of black steel sheets may rust over time. So it is necessary to sandblast first and finally use epoxy paints.

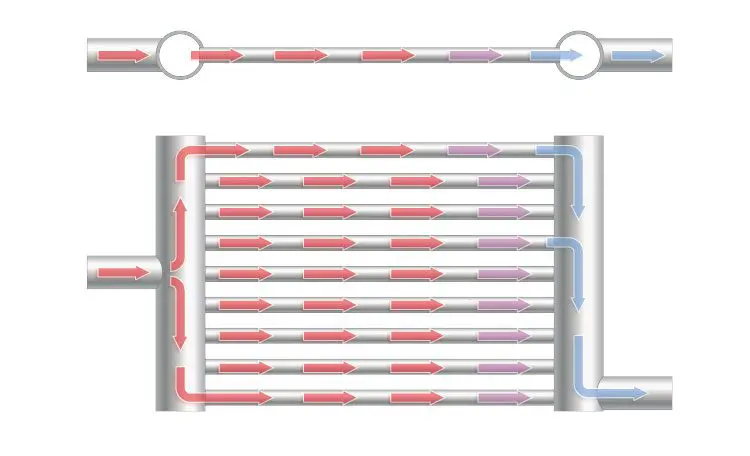

Coil

Coils or copper pipes are other components of the coil tank whose job is to pass hot water and steam through the boiler to eventually lead to the transfer of its temperature to the cold water in the tank. The coils are installed in two types of U-shaped and Helically in the body and their number varies.

Leave a Reply