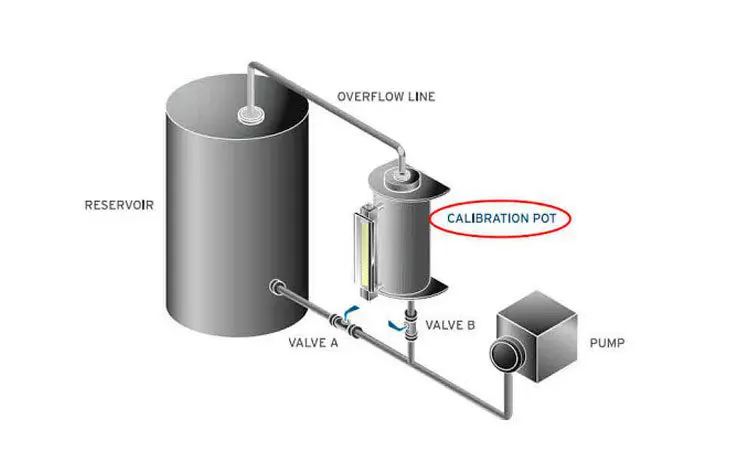

Calibration pot design

One of the most important points to consider in designing a calibration pot is how to size and calibrate the device. In general, according to the standards for calibration pot design, for large pumps the size of this equipment is one-minute pump discharge and for small pumps, two minutes’ pump discharge is considered. Other important items in the design and construction of calibration pots are the material used for the body and other connections in them. Strong glass is often considered for their body and stainless steel is used for its holding parts to be sufficiently resistant to chemicals.

Making a calibration pot

Seven Industrial Group is one of the largest design, production and manufacturing teams of calibration pots in different sizes. It should be noted that all products designed and built in this complex are under the supervision of professional and experienced engineers in the field of water and wastewater treatment. Due to the high variety of products and equipment of Seven Industrial Group, we suggest that you contact the experts for a free consultation before buying a calibration pot.

Calibration pot price

The price of the calibration pot or calibration cylinder is measured based on the material of the pot body and also their size. Due to the fact that the material and size of each of these products are determined at the design stage of the calibration pot and based on the place of installation and use of this equipment, so the prices are completely different. To inquire about the price of the calibration cylinder, you can contact Seven Industrial Group through the communication channels mentioned at the bottom of the page.

Advantages of pot calibration

· The most important advantages of calibration pot are the following:

· High accuracy in determining the injection pump flow

· Easy design, production and maintenance

· Design and production based on the type of chemicals desired

· Low calibration tank price

· Requires little space to install them in different environmental conditions

Application of calibration pot

In addition to the main application of the calibration tank, which is to measure and adjust the flow rate of chemicals according to fluid conditions, this group of equipment can be used for other applications as well. The most important applications of calibration pot are the following:

· Use the calibration pot as a suction line accumulator

· Check valve performance test after injection pump (if the fluid level in the calibration tank changes at the end of the pump course at once, it indicates a failure in the pump check valve)

· Precise injection of chemicals based on the desired flow without the need for manual adjustments

Leave a Reply