Making a diffuser

Haft Industrial Group is one of the most experienced teams in the field of design, production and manufacture of water and wastewater treatment equipment, which has included the production and manufacture of deep aerators in its activities. The products produced by this collection are all under the supervision of experienced and professional engineers in the field of water and sewage and are in full compliance with current world standards. To know the features used in each of the products and the type and model of deep aeration, the experts of Haft Industrial Group are ready to provide advice before buying large and fine bubble diffusers.

Deep aeration price

The price of deep aeration is determined according to its general shape (disc, tubular and plate), the size of the bubbles produced by them (small and large bubbles) and the material and material used for the body and other connections in the device. Due to the very high variety of these products, we suggest that you contact the Haft Industrial Group to inquire about the price of disc and tube diffusers through the following communication channels.

Deep aeration price

The price of deep aeration is determined according to its general shape (disc, tubular and plate), the size of the bubbles produced by them (small and large bubbles) and the material and material used for the body and other connections in the device. Due to the very high variety of these products, we suggest that you contact the Haft Industrial Group to inquire about the price of disc and tube diffusers through the following communication channels.

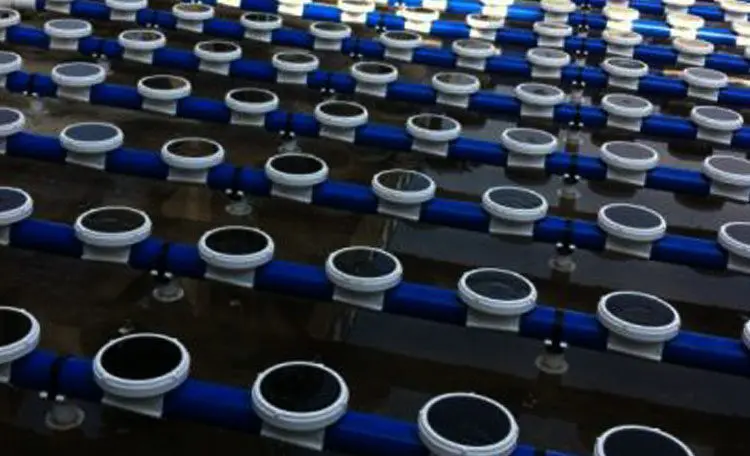

Application of deep aeration

Very high variety in the types of deep aeration devices and large differences in the size of the bubbles produced by these products can be used in different environments. The main applications of large and fine bubble disk diffuser systems and the reasons for making deep aeration can be mentioned as follows:

· Aeration of wastewater treatment by activated sludge method

· Industrial wastewater treatment such as textiles and drug factories

· Treatment and aeration of fish ponds and other aquatic animals

· Lagoon and successive SBR canals and reactors

· Ozonization of wastewater treatment plants and swimming pools

· Domestic, industrial and municipal wastewater treatment

Leave a Reply