How to design a Manual Bar Screen?

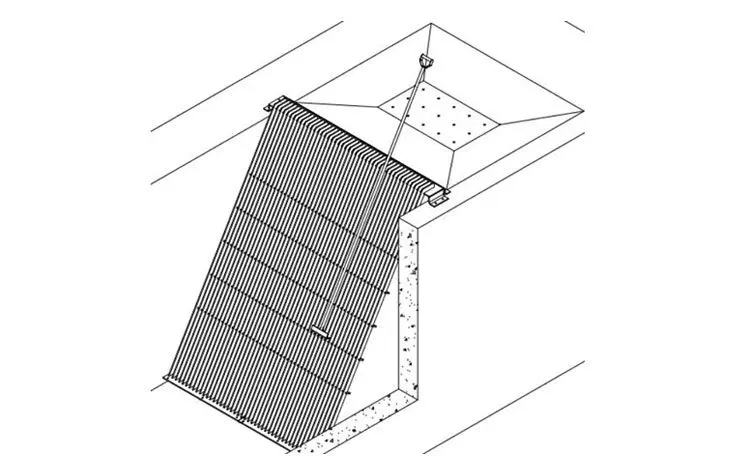

Manual Bar Screen is designed in such a way that we first consider the size of 7.5 to 15 cm from the inlet pipe of the device channel. The reason for this is that in case of screen clogging, the sewage does not return to the sewage collection system. Here is the basis for designing and building a Manual Bar Screen.

The basics for designing this unit are as follows:

Usually the distance between the bars is considered to be 10 to 50 mm and the width of the bars is considered to be 10 mm.

The velocity of the fluid passing through the rods is considered to be 0.6 to 1.

If the average flow of wastewater is greater than 150 liters per second, the Mechanical Trash Rake Bar Screen is used.

According to the basics; Select the flow rate of the fluid between the rods and then by dividing the average flow rate by the said velocity, the sum of the open surface between the rods is obtained:

We calculate the height of the sewage in the canal from the manning relation in the sewage inlet pipe to the canal and denote it by h1.

- In this step, by dividing the surface obtained from the previous step (A) by the height h1, we calculate the total width between the bars b1.

- In the next step, by dividing the sum of the open widths of the bars by the width of each bar we have chosen in the basics, the number of open spaces and finally the number of bars is calculated.

- Finally, with the help of the obtained values, the width of the B channel that is placed on the bar screen can be calculated:

b 2 is the width of the bars themselves.

In the next steps, the velocity of the fluid before and after the screen as well as the velocity of the fluid between the bars are determined.

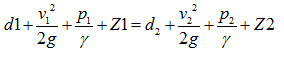

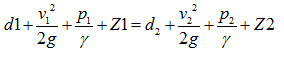

First, we calculate the height of the sewer before the screen bars with the help of Bernoulli relation.

Then we calculate the speed of the drain before the rod.

- From the above relation, assuming that z2 and the pressure are zero at the beginning and end, the height d2 can be calculated.The velocity in the section before the bars is equal to:

- The speed of sewage passing through the bar is equal to:

- As the sewage passes through the rod, there is a drop in the sewage pressure, the value of which is calculated from the following equation:

- Finally, the height of the sewage after the garbage collector is calculated as follows:

From the above relation d3 is calculated and finally velocity after passing the screen.

The section after the screen is of particular importance because it is to be connected to the next unit. Therefore, a controller is used to control the sewage. In fact, this controller also plays the role of overflow for sewage transfer.

Production and manufacture of Manual Bar Screen

Seven Industrial Group is a manufacturer of manual and mechanical garbage collectors and other wastewater treatment equipment that all stages of design and manufacture of manual and mechanical garbage collectors are carried out under the supervision of engineers and technicians in this field. Before buying the bar screen, the experts of this collection provide the necessary tips and advice according to the installation environment of this equipment to make the best purchase.

Manual Bar Screen price

The price of Manual Bar Screen is determined based on various factors such as type (rod or mesh), size and number of rods (fine and coarse grain), rod material and body of the device and size and dimensions used to design and produce it. To be. Therefore, to inquire about the price of Manual Bar Screen, we suggest using the communication channels mentioned at the bottom of the page

Leave a Reply