Desalination system control equipment and tools

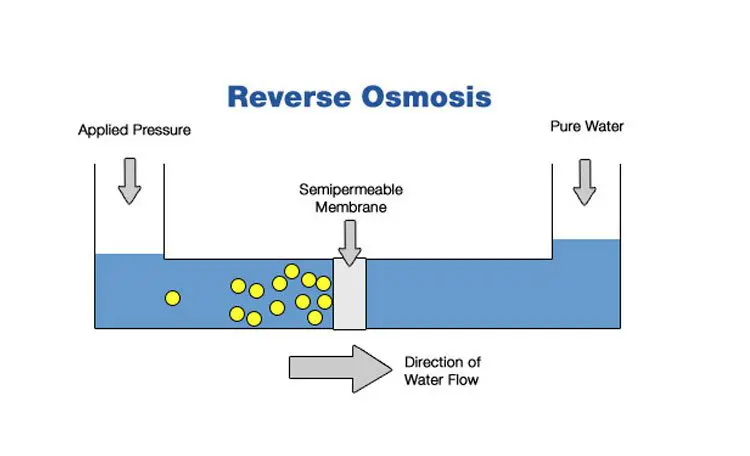

The process of transferring water through a semi-permeable membrane and removing ions, salts and contaminants requires pressure, which is the amount of pressure applied to the water according to the amount of contamination and other things. For this reason, control equipment is used in different parts of the device to finally achieve water output by removing more than 98% of salts and 100% of bacteria and viruses. The most important control equipments used in the industrial desalination machine produced in Haft Industrial Group are:

· Flowmeters

· Steel pipes and fittings or Super Pipe and V.C for two lines under pressure and low pressure

· Flow regulating valves, sampling valves and pressure relief valves

· Electroconductivity meter (conductivity meter)

· PH-meter

· Pressure Gauge Manometer

· Low Pressure Switch & High Pressure Switch

Advantages of industrial water purifier

RO industrial water purifier is now widely used not only in industry but also in agriculture and household sectors. The reason for the high demand for reverse osmosis to desalinate water is the many advantages of this method of water treatment, the most important of which are the following:

· The system is more economical than other methods

· Less energy consumption compared to other water purification methods

· Ability to work continuously without the need for periodic stops

· Ease of working with the device and reducing maintenance costs

· Prevention of bacteria, viruses and febrile substances (PYROGENS) from passing through the membranes

· Possibility of returning concentrated water to the environment or reusing water in the device

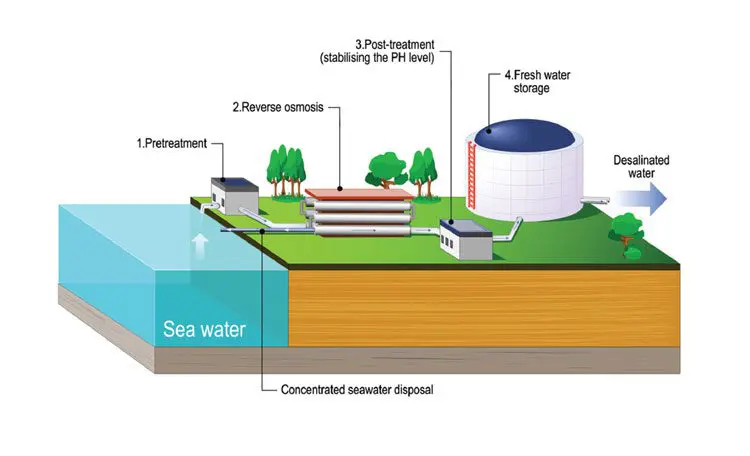

Application of water desalination (reverse osmosis)

The use of seawater and groundwater with high solutes and salinity, as well as the recycling of wastewater in industrial sectors is one of the best solutions to deal with drought and water shortages. RO desalination plant largely solves these problems and is used in various industries due to the removal of ions, bacteria and viruses and salts smaller than 0.0001 microns. The most important uses of reverse osmosis are:

· Preparation and production of drinking water from salt water

· Preparation and production of water required for rapid growth of livestock and poultry

· Supply and production of suitable water for significant growth of plants and agricultural uses

· Supply and production of process water of pharmaceutical and cosmetic factories

· Production of water for steam power plants and combined cycle

· Water supply and production of boilers, refrigeration systems and heat exchangers

· Water supply and production of dialysis machines in hospitals

· Recycling of industrial effluents

Industrial water desalination price

The price of desalinators varies depending on the type of operation, size, capacity and environment used by each. So that home water desalination is cheaper than industrial type with large size and capacities. To inform and inquire about the price of the industrial desalination device, all you have to do is contact Haft Industrial Group through the communication channels mentioned at the bottom of the page.

Manufacture of RO industrial desalination plant

Production of reverse osmosis desalination machine in different capacities and with different applications such as industrial, domestic, marine, agricultural, etc. is one of the services of Haft Industrial Group. This company with more than 30 years of international and domestic experience in manufacturing water and wastewater treatment equipment is ready to provide services to domestic and foreign companies and customers. Experts of Haft Industrial Group are ready to provide the necessary advice before purchasing an industrial desalination plant “RO” and offer different options depending on the purpose of installing reverse osmosis in the desired environment.

Leave a Reply