Components of human and sanitary wastewater treatment package

Depending on the type of wastewater and the place of use of this package, different sections are considered for it. The set of packages produced by Haft Industrial Group has several accessories, the most important of which are:

Each complete wastewater treatment unit has the necessary accessories such as garbage collection equipment, pumping system, aeration blower, clarifier, sludge digester, disinfection tank, and electrical panel along with cabling and communication pipes.

Package tanks are made of carbon steel sheets and profiles and are protected against corrosion by primers and epoxy coatings. Some of the tanks intended for this package, which are mostly used in low-capacity environments, are made of polyethylene and fiberglass, which act as a wastewater treatment reactor.

Design of wastewater treatment package

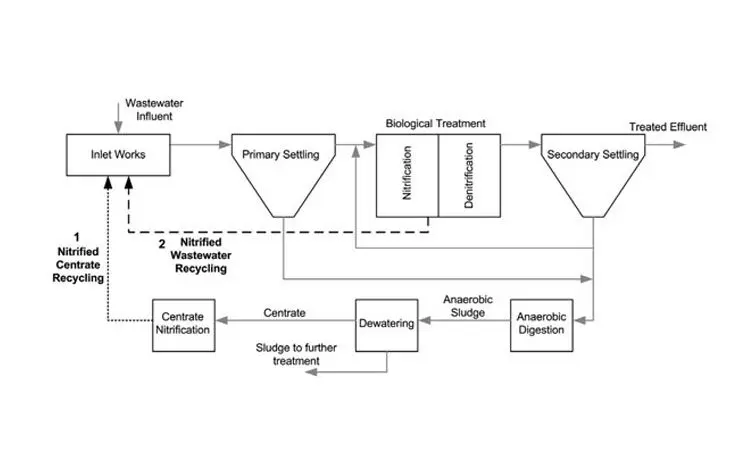

Haft Industrial Group has considered several important principles and standards in designing the sanitary and human wastewater treatment package and based on this, unique features can be seen in its products. In designing and producing sanitary and human wastewater treatment packages in Haft industrial complex, four important parts have been considered, which are:

· Ventilation pool

· Secondary sedimentation pool

· Sludge digester

· Chlorination section

Aeration pool: Aeration in this method is in the form of deep aeration (using diffusers). In this section, biodegradation of incoming wastewater takes place. Because it is odorless, the aerobic method is usually used.

Secondary sedimentation pool: By decomposing the wastewater, the sludge produced by the aeration section is deposited in this part and part of the deposited sludge is transferred to the aeration part and the rest is transferred to the sludge tank so that the sludge is disposed of after digestion. The output of this section is transferred to the chlorination section by the V-notched located in the upper part.

Sludge digestion: The sludge from the secondary sedimentation is stabilized and disposed of in this part.

Chlorination: To remove bacteria and harmful contaminants remaining in the wastewater, chlorination is done to increase the quality of wastewater.

Construction of the sanitary and human wastewater treatment package

Haft Industrial Group is one of the largest manufacturers of sanitary and industrial wastewater treatment packages, which has more than 30 years of experience in the production and manufacture of wastewater treatment packages and industrial water and wastewater treatment equipment in general. Over the years of activity in this field, this group has succeeded in implementing major domestic and international projects. Adherence to international standards in the design and construction of sanitary wastewater treatment packages and high diversity in products and their unique design based on the type of order under the supervision of experienced engineers is one of the main features of Haft Industrial Group products. The experts of this collection are ready to provide the necessary advice and guidance before purchasing the sanitary wastewater treatment package.

Price of sanitary wastewater treatment package

Packages produced in Haft Industrial Group have several features according to the conditions of the installation site. Therefore, the price of the sanitary and human wastewater treatment package is not the same and is determined based on the capacity of the tanks, capabilities, materials used in different sectors, and so on. To inquire about the price of the sanitary and human wastewater treatment package, you can use the communication channels mentioned at the bottom of the page.

Application of prefabricated sanitary waste package

Wastewater produced in different environments is completely different in terms of organic matter and pollutants in them. As a result, the need to treat them in some environments is necessary and the only way to prevent harm to humans and the environment. The prefabricated sanitary wastewater treatment package is mostly used in situations where it is not possible to connect to the central municipal wastewater, and the type of pollutants in them are completely harmful. Accordingly, the main application of human and sanitary wastewater treatment package is:

· Military and training camps

· Residential settlements that do not have access to central sewage

· Hospitals and treatment clinics (hospital wastewater treatment package)

· Large industrial factories near rivers and lakes

· Leisure centers, hotels, airports, travel terminals, and so on

Advantages of using human and sanitary wastewater package

As mentioned, the products of water and wastewater treatment of Haft Industrial Group have been used in various industrial, military and residential environments. The main reason is the positive and unique advantages and features that are considered in this group of sanitary wastewater treatment of this group. The most important advantages of using this package are:

· Including the necessary efficiency in the treatment of various wastewaters based on its proper design

· Having all the units and systems required for treatment and not needing any accessories to perform treatment operations

· Occupy little space and the possibility of dimensional change based on the conditions of the installation site

· Ability to transport from the manufacturing workshop to the package installation site

· High speed in construction, installation, and commissioning of the sanitary wastewater treatment package

· Upgradeability due to changes in environmental conditions and treatment plant

· Low energy consumption

· Requires little space (due to special design)

Implementation of projects for the production of sanitary wastewater treatment packages

Due to the high history and experience in Haft Industrial Group, this complex has presented large projects for military and administrative organizations and residential towns, including the following options:

· Phase 12 of Assaluyeh residential area

· 13-hectare dock in Shalamcheh

· Baku Caspian Fish Company

· Iran Khodro and Iran Khodro Diesel factories

· Pakshoma Company

· Khatam Al-Anbia Camp

· Madain Hospital of Tehran

· Sapco Company

· Kashan Samyar Automotive

· Dar Al-Tawhid Hospital

In order to register the order and communicate with Haft Industrial Group and receive information about the price of the sanitary wastewater treatment package and other products of this collection, you can use the communication channels mentioned at the bottom of the page.

Leave a Reply