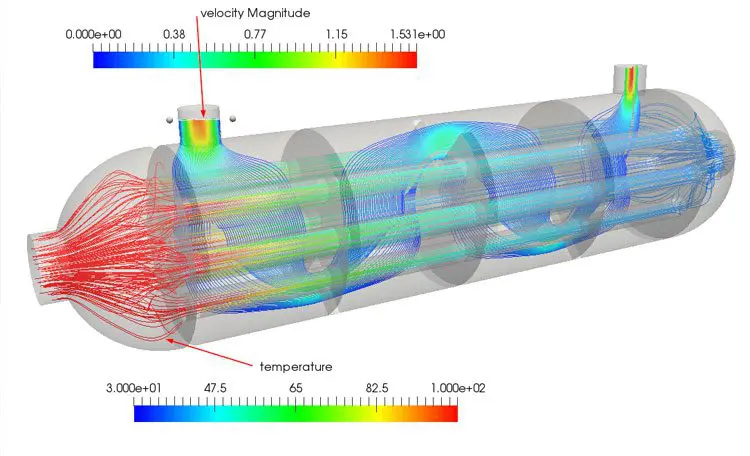

Types of shell-tube heat exchangers

The classification of heat exchangers is based on various factors, one of the most important of which is the shell and tube heat exchanger standards. Due to the fact that in the design and production of shell and tube exchangers, the TEMA standard is followed, as a result, there are exchangers in different classes and based on the desired environment, the most important of which are class R, C, B. Class R exchangers are mostly used in oil and gas refineries and Class B is produced for chemical projects and processes. Of course, it should be noted that according to this standard, heat exchangers are produced in different classes, each of which has different characteristics. Class A, B, C, D, E, F, G, H, etc. heat exchangers are among these.

In another division based on header or cap, this type of heat exchanger can be divided into the following groups:

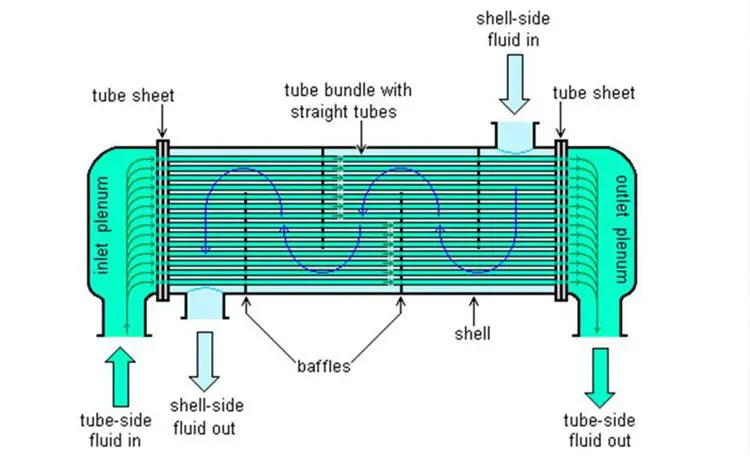

Fixed tube sheet exchangers

In this group of exchangers, which are in class L, M and N, the fluid tubes are fixed on a plate called a tube sheet. Cost-effectiveness and simple construction and design in a short time is one of their most important features and they are in group 1 pass exchangers. In other words, in the construction and design of heat exchangers with fixed sheet tubes, straight and unconnected pipes are used, which are mechanically cleaned and there are no leaks in them.

Exchangers with U-shaped pipes

In order to increase the contact of the pipe fluid with the fluid inside the shell, U-shaped pipes are used in heat exchangers, which cannot be cleaned mechanically. The price of the U-shaped heat exchanger is at the Inexpensive level compared to other exchangers and it will be quite affordable to buy it.

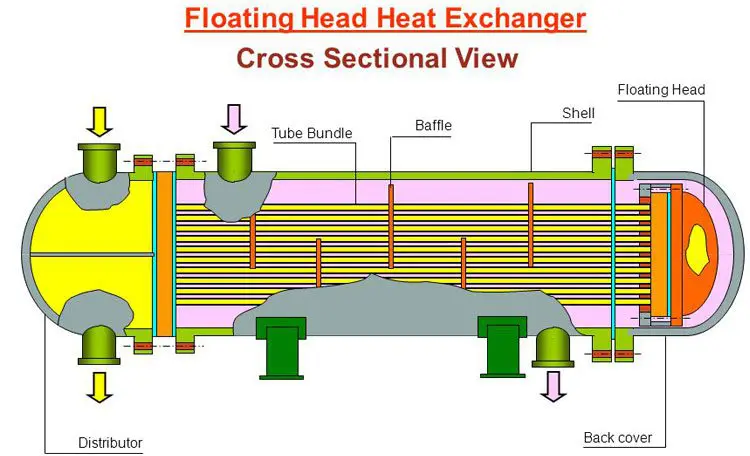

Floating head heat exchanger

Floating head heat exchanger, which are in classes W, T, S and P, the end of the exchanger is not welded to the shell. At the front of the exchanger, a sheet of larger diameter pipe is welded to the shell. One of the most important features of this group of heat exchangers is their high resistance to thermal expansion and easy cleaning.

Leave a Reply