Reasons why it is important to remove water hardness

As mentioned, water hardness removers are widely used in domestic and industrial applications due to the harmful effects of salts in water on various environments. The main reasons for the importance of removing water hardness are:

· Calcium and magnesium chlorides in water severely corrode boiler walls, water pipes, and other metals.

· Calcium and magnesium sulfates eventually build up on walls and waterways in power plants, home water pipes, and water heaters.

· The presence of more than 3000 mg of sodium chloride in water causes salinity, bad taste and non-drinkability.

· The CO2 released from the potassium and sodium carbonate and bicarbonate will react with the water to produce carbonic acid. Carbonic acid has a strong negative effect on the pipes and walls of industrial boilers.

· Excessive hardness in water is harmful to human health and includes the formation of kidney, bladder and indigestion stones.

· Sedimentation in high pressure boilers, which reduces the efficiency due to low heat transfer and thus increases the operating temperature of the boiler by the user to compensate for the heat transfer deficit and consequently increase fuel consumption.

· Sedimentation in cooling towers, chillers and other heating and refrigeration systems and reducing their efficiency or failure of the entire system

· Due to the hardness of the water, the washing power of all soaps is reduced so that the efficiency of detergents in hard water is half that of soft water.

· In the textile and dyeing industries, it causes a decrease in dye quality.

Application of water softener

As mentioned, the hardness of water will have a negative effect not only on people’s health but also on the quality of products produced in the industry. As a result, it can be used in various fields, the most important of which are the following:

· Prevent sedimentation in expensive devices

· Reduce hardness and purify drinking water

· Prevention of clogged pipes

Important steps in getting water hardness

At present, water softener is produced in different factories, each of which has special features and capabilities. But before starting the process of removing water hardness, it is necessary to answer some important questions, which are:

· What are the types of substances and ions in water? What is the value of each? Is the water analysis completely done?

· Is water hardness temporary or permanent? Is it carbonate or bicarbonate?

· According to the data obtained from water analysis, how many chemicals are needed and what kind of them are needed?

· Possibility of mixing water with chemicals

· Calculate the water hardening time

· Separation of sediment and extraction of soft water

Types of methods for removing hardness from water

The methods of obtaining soft water and removing the salts in the water vary according to the amount of salts, their type, as well as the industry that uses soft water. In general, there are several common methods for water softener, the most important of which are the following:

· Resin Softener

· Magnetic Softener

· Reverse osmosis

· Electronic Softener

· Use a carbon filter

In designing and manufacturing water softener, the type of device is determined according to the process and method used to separate salts and ions. Each of these devices uses different methods to remove water hardness. For example, some people use chemicals to remove calcium and sodium and convert them to sodium salts. In some devices, magnetic methods are used and can be very effective in capturing the hardness of water, and in some, combined methods are used.

Resin Softener

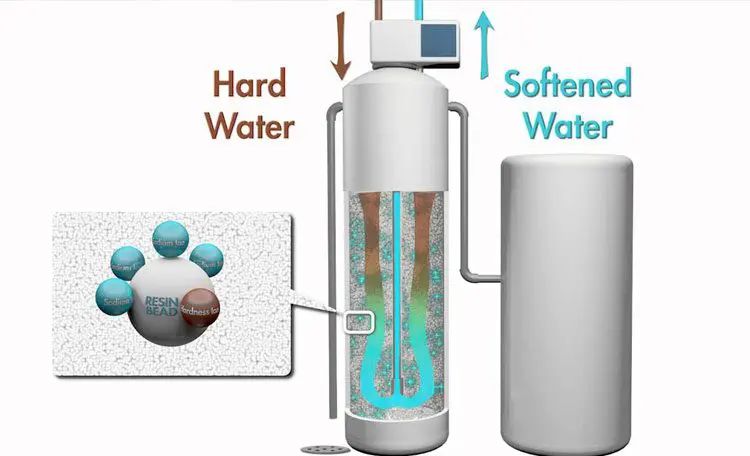

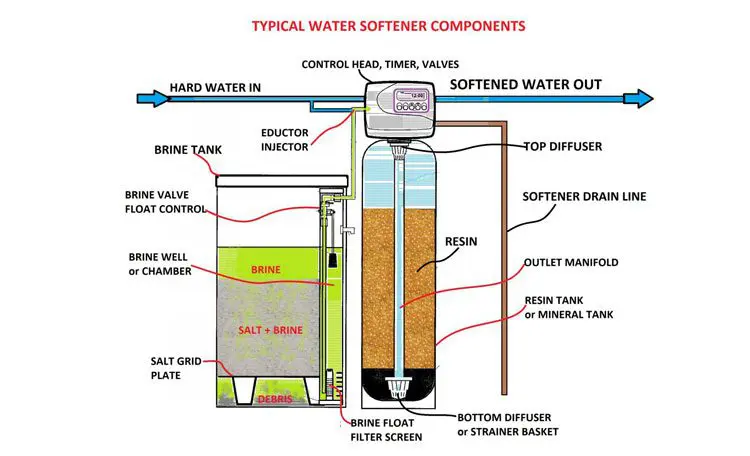

One of the common methods of de-hardening is the use of resin softeners. The device consists of a metal cylinder inside which the descaling agent (ion exchange resin) is placed. These resins can exchange sodium ions with calcium and magnesium ions in water and replace them. Commissioning, operation and reloading of the device can be done manually and semi-automatically or fully automatically. Resin softeners used in water treatment are mostly in the form of metal cylinders, in which resin particles are placed.

The use of resin in water purification and its hardness removal is in two types of automatic and semi-automatic, each of which has special characteristics. One of the differences is the way the Softener is regenerated and cleaned. In the fully automatic Softener, the washing process, which is often backwashing, is performed automatically without the need for operator or human intervention, and the resins are regenerated. In contrast, for cleaning resins in the semi-automatic Softener type, the operator performs this process.

One of the most important applications of resin softener is resin softening in leather, textile, carpet washing, dairy and food industries, oil and petrochemical industries, concreting and construction.

Leave a Reply