Head Office: Tehran, Shariati, Taleghani Street, 1 Amol, No. 75, V.25

- Home

- Water Purification

- Water Tratment

- Sanitary wastewater treatment package

- Industrial wastewater treatment package

- Corrosion inhibitor package

- Chemical preparation and injection package

- Flocculant package

- Floating surface aerator

- API grease trap

- Air Lift pump

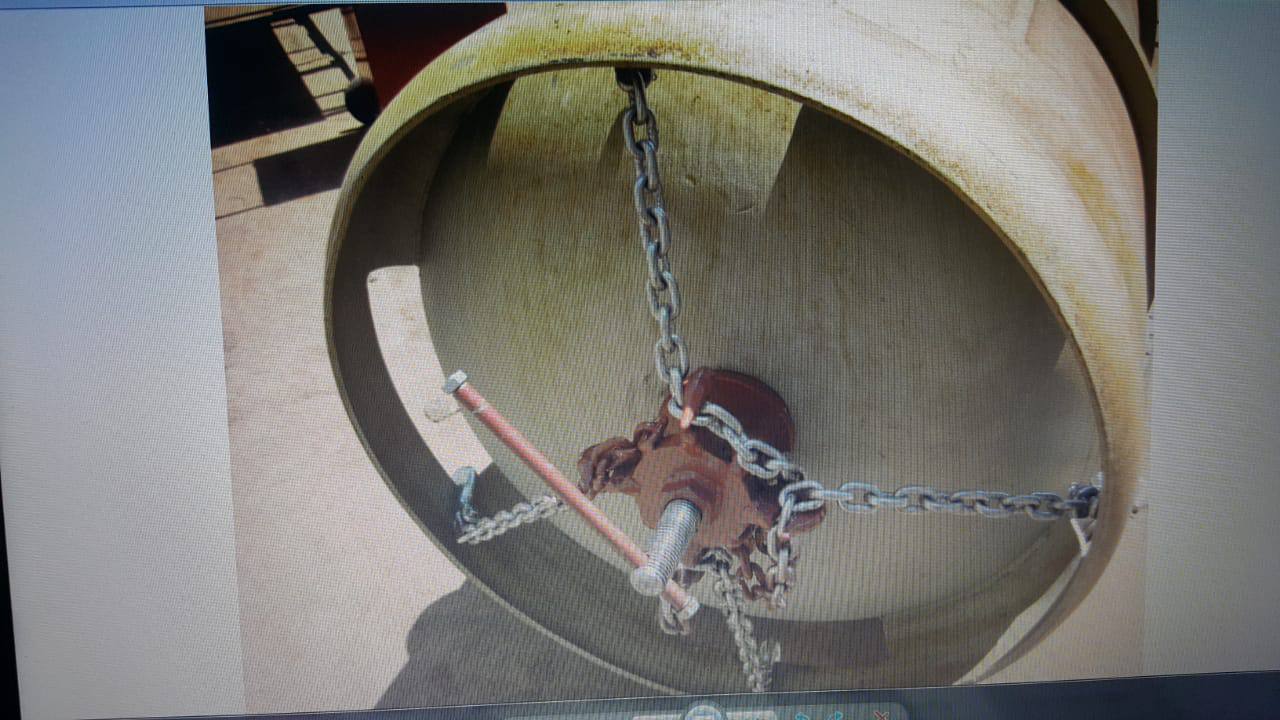

- Rotating sludge scraper

- Sludge scraper Bridge

- Manual Bar Screen

- Dual mesh bar screen

- Raked bar screen

- UASB wastewater treatment package

- Clarifier

- Press filter or pressure filter

- CPI degreaser

- Reciprocating Sludge Scrapper

- Grit Classifiers

- Water control gate

- Dissolved Air Flotation DAF

- Oil Skimmer

- Chemical injection pump (dosing pump)

- Calibration pot

- Deep aerator or disc and tube diffuser

- Half bridge sludge scraper

- Fixed surface aerator

- Chemicals

- Oil Purification

- Other Products

- Company

✕

Leave a Reply