What is anionic resin?

This group of resins have active anions and are able to remove nitrates and chlorides in water. This group of resins also have different functions based on their type, which are grouped as follows:

Strong anionic resin

This group of resins have active anions and are a very practical option to reduce the amount of chlorine in water as well as mineral acids. In the strong type, these resins are able to destroy the anions in the water.

Weak anionic resin

Weak anionic resins have 4 amino groups and are able to remove the anion of acids such as nitric acid and hydrochloric acid. A very important point is that anionic resins are not able to remove the silica in water and have a higher resistance than the strong anionic type.

The difference between cationic and anionic resin

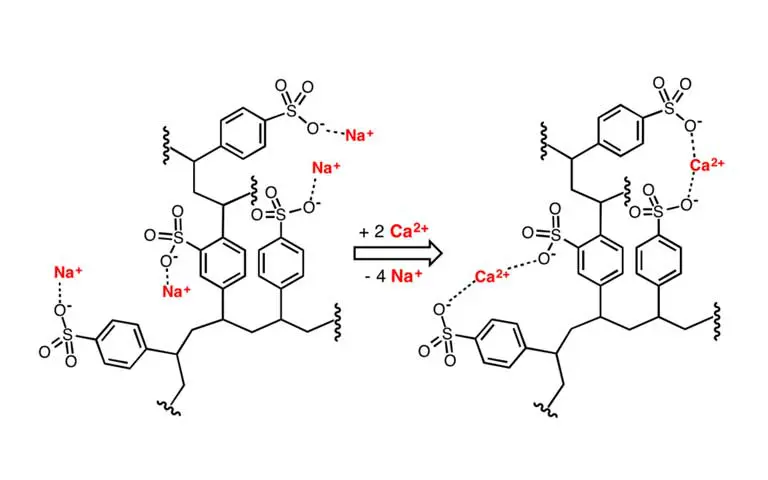

As mentioned, in some resin grains, there are active cations, and for this reason, they have a high power in exchanging and removing the existing cations. On the other hand, anionic resins are able to remove anions in water such as nitrates and chlorides and replace them with sodium present on the resin. Cationic resins are used to remove ions such as calcium, magnesium and iron.

Another difference between anionic and cationic resins is the type of material used for their regeneration. The continuous use of both types of resins will eventually lead to a decrease in their efficiency, and for this reason, anionic resins are regenerated with carbon hydroxide and cationic resins with sulfuric acid. It should also be noted that the amount of resin required to remove ions is different in both anionic and cationic types. In general, the required amount of resin is obtained from the ratio of the removed ions to the total ions in the water.

Strong Acidic Cation Resin

One of the strongest types of resin is the cationic type of strong acid, which removes all the cations in water very quickly. One of the most important features of this type of resin is that it does not change the pH of water, quickly removes all ions and cations, and can be regenerated with acidic solutions, water and salt.

Weak Acidic Cation Resin

Considering that acrylic-based resins are not able to remove all the cations in water, that is why they are called weak acids. According to the type of resin application and the degree of purity required from water and other fluids, both types of strong and weak acids can be used together.

Strong Base Anion Resin

Strong basic anion resins are the most widely used type of resin for separating anionic ions in acids. These resins can be divided into two functional groups, I and II, which have different properties. One of the most important features of this type of resin is its very high power in removing all anions.

Weak Base Anion Resin

Another type of resin is only able to remove anions in strong acids and cannot be used to remove carbonic acid and silicic acid.

The most widely used types of ion exchange resins

In addition to the above categories, ion exchange resins can be divided into several groups according to the type of ions that are absorbed and their exchange occurs. Among the widely used examples of resin grains in various industries, the following can be mentioned:

Calcium and Magnesium Selective Ion Exchange Resin: This type of resin is able to remove calcium and magnesium and reduce water hardness.

Iron and Manganese Selective Ion Exchange Resin: This type of resin, which has a high power in removing iron and manganese, is used in the extraction of minerals and also in the treatment of electroplating wastewater.

Boron Selective Ion Exchange Resin: This type of resin is in the weak anion group and has a high power in removing boron from the desired fluid.

Arsenic Selective Ion Exchange Resin: Arsenic, which is one of the most dangerous chemical elements, is removed with this type of resin in the shortest time.

Nitrate Removal Resin (Nitrate Selective Ion Exchange Resin): Due to the adverse effects of an excessive amount of nitrate in water, this type of resin is used to remove this element.

Application of anionic and cationic resin in water purification

As mentioned throughout the text, resin grains are very effective in reducing the hardness of water, as well as removing harmful particles in it and purifying water. Among the most important applications of anionic and cationic resins, the following can be mentioned:

Reducing water hardness with resin

The presence of calcium, magnesium and other particles and metals in water has led to an increase in its hardness, which causes many problems for human health and reduces the quality of water. For this purpose, equipment such as resin hardeners are used, in which a bed of silica and resin grains are implemented. The available silica reduces the volatility of the resin grains. Passing water over the resin substrate causes calcium and magnesium ions to be replaced by sodium in the resin. The constant replacement and exchange of calcium and magnesium ions with sodium on the resin grains eventually leads to a decrease in the strength of the resin bed. For this reason, it is necessary to regenerate the resin in different ways, including the use of salt and water solution and reverse washing.

Leave a Reply